Value without compromise

Your trusted experts in the manufacturing, fabrication, and distribution of needles, cannulas, hypodermic tubing, and precision metal components.

Value without compromise

Your trusted experts in the manufacturing, fabrication, and distribution of needles, cannulas, hypodermic tubing, and precision metal components.

GloMED Scientific Inc (formerly GloMed Inc) has earned the trust of leading medical device manufacturers during forty-plus years of OEM experience in over 20 countries. We’ve helped our customers reduce costs and increase transparency, with faster turnaround times that speed product development and market readiness.

This customer service is hard to match. For example, we can manufacture 500,000 feet of tubing in 6 to 8 weeks when most of our competitors would take upwards of 12 weeks. And we can supply 10,000 feet of tubing as a minimum, where our competitors might require a minimum of 50,000 feet.

GloMED has earned respect for our ability to accept and quick-turn quantities smaller than the usual industry minimums, in manufacturing facilities that maintain all relevant ISO certifications.

We’re proud that our quality products are used confidently in hospitals, clinics, labs and manufacturing environments worldwide.

Hypodermic tubing

Needles / cannulas

Metal components

Low-cost high-quality manufacturing

Multiple assembly lines for faster turnarounds

Capable of a wide range of processing for tubing, including bending, drilling holes, and shaping tips

We have a strong connection with AccuSpire, the website where purchasers can easily find FDA-approved medical products. AccuSpire connects a wide range of GloMED Scientific customers to their markets. On AccuSpire you can be represented along with our 30 other manufacturers and showcase your OEM products to thousands of medical device professionals.

For hypodermic tubing and pipes

ISO 9001:2015

ISO14001:2015

ISO45001:2018

IATF 16949:2016

For custom hypodermic needles

ISO 13485

For custom precision metal components

ISO9001:2008

You can have confidence in the quality of GloMED Scientific custom hypodermic tubing and blanks. And our pricing and quick-turn customer service are outstanding.

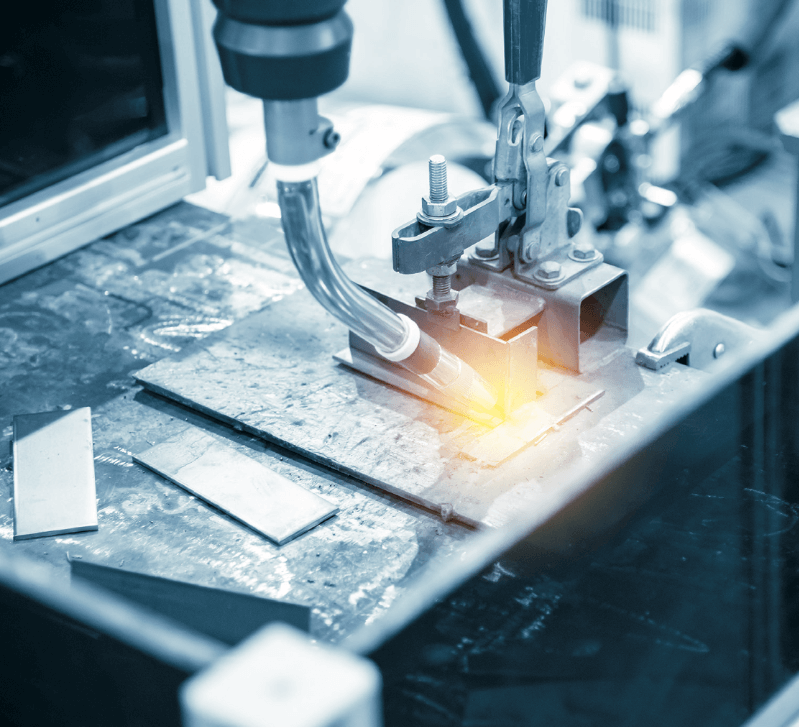

From welding and cold-drawing through bright annealing, our processes for creation of tubing are based on years of expertise. They are designed to produce the quality you need. The result is a reliable product standard at a price and service level that is unmatched in the industry.

We can manufacture hypodermic tubes that range from 10g. to 30g. in custom-cut lengths, in these standard thicknesses: Regular Wall, Thin Wall, and Ultra-thin Wall.

We can process custom orders as small as 10,000 units, 10g. to 30g.

In addition to custom hypodermic tubing, for over 40 years GloMED Scientific’s exclusive partner facilities have manufactured a wide range of high-precision needles and cannulas as well as custom hypodermic needles and various other custom trocars and cannulas.

We can produce complete needles, custom needle tips, cut blanks and other tubular components — including performance of operations such as bending, precision holes, etc.

Our custom projects can range from 10,000 cannulas to 10 million custom needles.

GloMED Scientific’s core competency is in grinding a variety of needle points, trocars and trephines on tubing that can range from 6g. through 30g., according to customer requirements.

With the advent of new technologies and demand for a variety of point geometries, we have developed many special grinding systems and processes. As a result we can offer many point geometries. And you can specify custom point geometry as well;

we have fully capable machine- controlled grinding systems and processes.

We use fully automated PLC/CNC- controlled special point grinding machines, integrated with micro glass bead blasting, for a consistent high quality of needle bevel. Our centerless grinder and surface grinder, and even the trephine (biopsy punch) grinding machine, are CNC-controlled, with an autoloading system.

Blunt end square cut

Blunt end with radius

Lancet bevel

Back cut bevel

Deflected non-coring septum point

Solid trocar

Closed round end

Flared end

Threaded end

Solid fill pencil point

Blunt end chamfered edge

Blunt end tapered

Deflected point

Blunt end

Trephine cutting point

Biopsy outside cutting edge Cournand style

Solid bevel flat point

Closed swage pencil point

Internally threaded

Grooves

Echo-genic

Blunt cut and square cut

In addition to tubing, GloMED Scientific manufactures precision custom components to meet the needs of customers creating everything from furnaces to switchgear, from automobiles to heavy-duty circuit breakers.

More than four decades of experience have made our metal components facility expert at manufacturing the most intricate of components

— including brass pipe and hydraulic fittings, hose couplings, brass and stainless steel hex-nuts, and heat-sinks.

Our ISO-certified and FDA-registered partner facility can manufacture components from any type of material, including free-cutting brass, lead- free brass, high-tensile and silicon brass, cadmium copper, ETP copper, bronze, stainless steel and aluminum.

GloMED custom projects can range from quantities of 10,000 to 10 million.

We have dozens of machining fabrication capabilities for precision grinding, cutting and bending.

Grit blasting

Etch marking

Bending

CNC turning and milling

VMC machining

Electrical Discharge Machining (EDM)

Wire cutting

Automats

Automated swaging

Power pressing

Micro drilling

Forging

Wire straightening

Centerless grinding

Laser cutting

Die forming

Tumble/vibro polishing

Micro-hole drilling

Custom fabricated parts

Silver brazing

Silver plating

Siliconizing

Passivation

Bright nickel plating

Aqueous cleaning

Ultrasonic cleaning

Electro polishing

GloMED Scientific distributes stainless steel hypodermics and stainless steel tubing, custom needles and medical components, to more than 30 global medical device manufacturers in over 20 countries — trusted products that save costs and increase transparency for hospitals and clinics worldwide.

Our cost benefits and faster turnaround times are packaged with unparalleled customer service. All our tier one customer service is based in the U.S.

We source from ISO-certified facilities operating in a combined 425 thousand square feet of manufacturing space, whose 40-plus years of experience mean significantly faster turn times and the ability to quickly deliver smaller project quantities.

Need custom hypodermic stainless steel tubing, needles or cannulas for your new project or trying to reduce cost of your existing cannulas? We can help with both. With GloMed you could save anywhere from 10% - 50%. Ask us how at info@glomed.biz

GloMED Scientific Inc is also distributes thousands of medical devices and supplies from leading American, German and International Medical device manufacturers which includes surgical instruments, sterilization trays, Punctal plugs, dry eye products, dermatology blades and more for the US and Indian market

Contact us at INFO@GLOMED.BIZ to explore if your products are a good fit for our channel

HYPODERMIC NEEDLE

Our supreme quality Disposable hypodermic needles are used as medical tools, commonly used with a syringe to take blood samples and to inject medicines. Our hypodermic needles are used for many purposes like Artificial insemination guns, dental, disposable needle, instrumentation etc.

STAINLESS STEEL WELDED TUBES

As a leading manufacturer and exporter of top quality Stainless Steel Welded Tubes, our products are renowned for its rigidity, leak proof, and durability. It is also easy to install. The machineries deployed in the production of these tubes are imported from Germany.

Shop Ophthalmic Instruments, Cannulas, Blades, Sterilization Trays, Tonometers, Sutures, Dermatology Products, Punctal Plugs

Shop Veterinary Needles, Animal Feeding Needles and Other Special Procedure Needles For Veterinary Use

Shop Sterilization Trays made of Plastic Or Aluminum. Custom Hypodermic Stainless Steel Tubing